The Thinking Pod Innovations Ltd.

Ingenuity Centre

University of Nottingham Innovation Park

Triumph Road

Nottingham

NG7 2TU

Our Technologies

Smaller, lighter, more efficient components

TTPi’s novel technologies enable us to create smaller, lighter, more efficient power converters and motor drive systems, which are essential in electric vehicles, renewables, dynamic industrial processes and green aerospace.

Using TTPi’s technology we can package components into lightweight, compact, modular units that will produce major savings in precious raw material use, energy, cost, and deliver a better performance compared to anything currently available.

We work with customers and collaborators to transform how they generate, manage, and use energy to create sustainable systems resulting in savings and environmental benefits, powering the push to Net Zero.

Ultra-Efficient Power Conversion

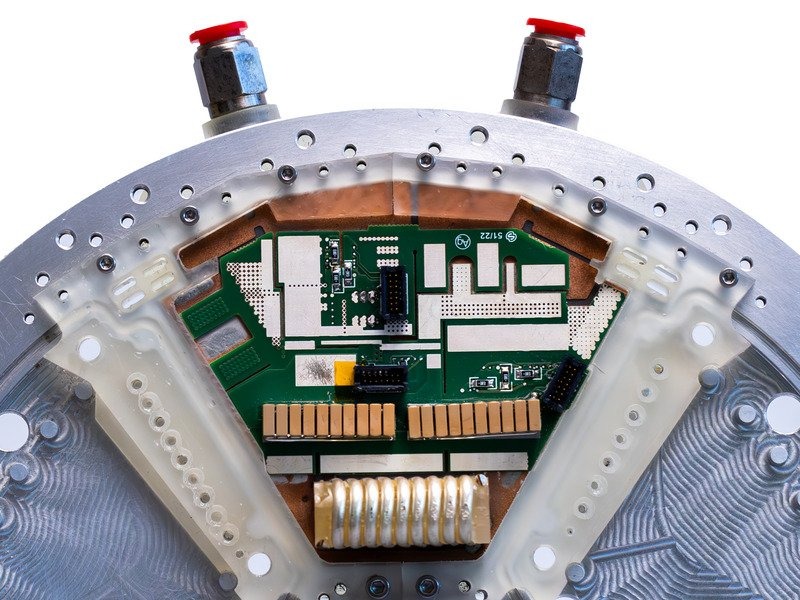

At TTPi, we specialise in advanced power conversion architectures, which utilise the latest semiconductor device technologies. By leveraging topologies like multi-level and hybrid multi-level inverters, Auxiliary Resonant Commutated Pole (ARCP) converters, matrix converters, in addition to novel isolated and non-isolated DC-DC architectures, we can deliver solutions that reduce electrical losses, weight and volume.

TTPi is particularly experienced in the exploitation of Wide Bandgap semiconductors, including GaN and SiC. Combined with suitable topology, they can dramatically reduce the size of passive components through high-speed switching and advanced control. We use machine learning and precision digital control to manage high performance power systems, enabling simplified, efficient designs with a reduced bill of materials.

Advanced Digital Control

Achieving the best performance in complex power converter topologies means having the right control systems in place to handle the speed, complexity and real time demands of intricate structures. At TTPi, we combine advanced digital control techniques powered by FPGA and advanced MCU products, with machine learning to enable sub microsecond control loop updates.

Energy systems and power converters are becoming increasingly dynamic, making classic control techniques ineffective. Hence, we develop self-optimizing, adaptable systems that adjust operating setpoints on demand, using neural networks. This means greater efficiency, faster response times, and more reliable performance. We have put this technology to work in projects for VIDAR, OCTOPUS, IFX Matrix, and the National Grid ESO.

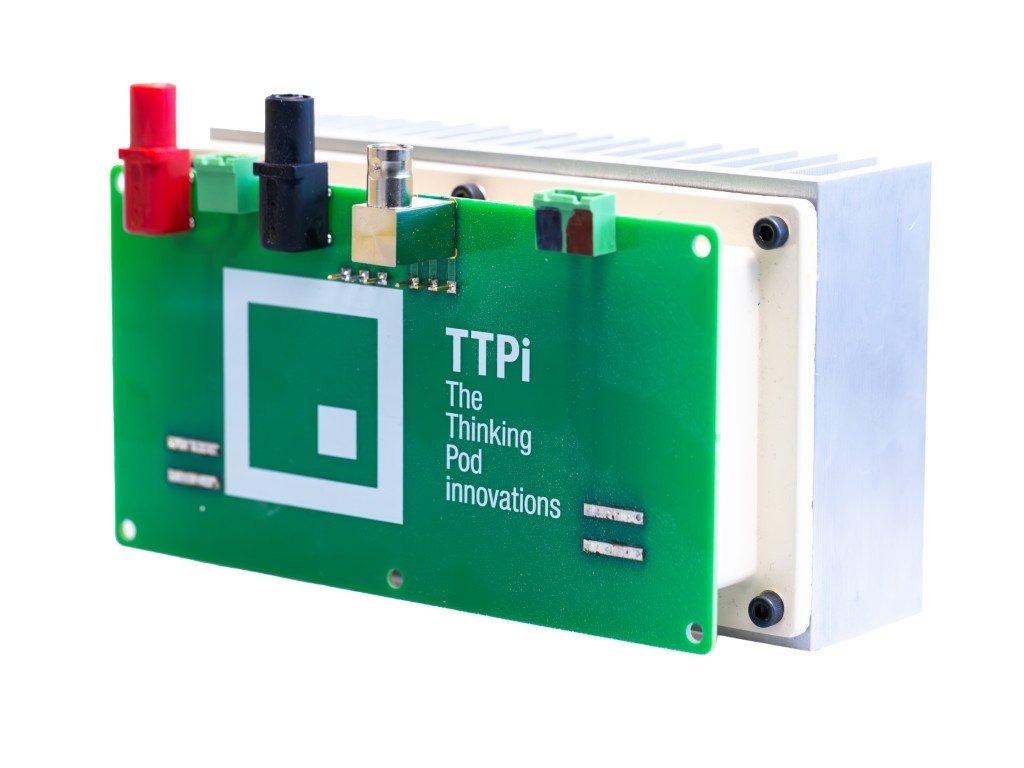

EMI containment and control

Managing EMI is a critical part of any power converter design – especially as systems become faster, smaller and more integrated. At TTPi, we tackle EMI at the source; containing, directing and dissipating the high frequency energy before it has chance to exit the system. Our proprietary IP allows us to integrate EMI filtering with the converter during early design stages. This approach not only reduces EMI effectively, but also saves space and weight. It is particularly advantageous when dealing with either embedded power module designs, or high-speed devices such as GaN or SiC.

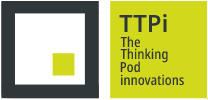

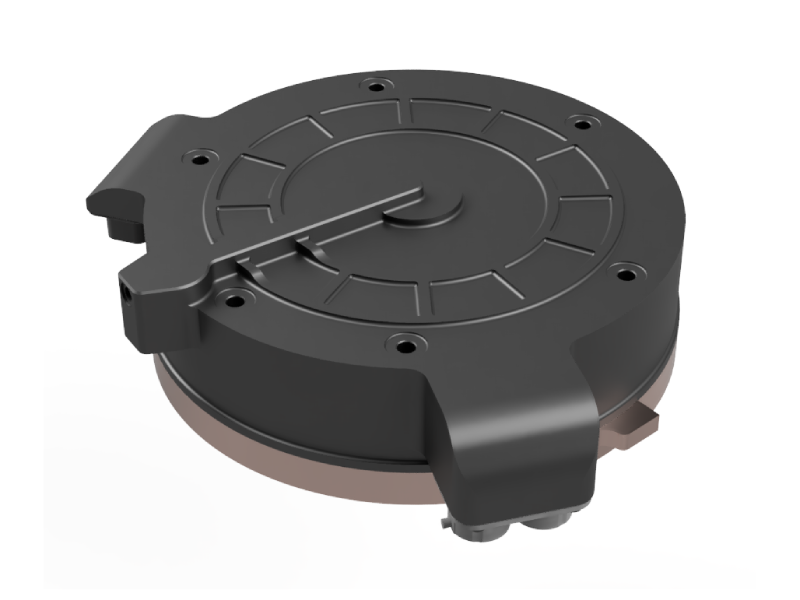

0ur first fully integrated ‘Converter-in-Package’ (pictured left) was developed as part of the ECOMAP project. It delivered a 20dB reduction in both common mode and differential mode conducted EMI emissions when using the integrated EMI filtering, in a GaN based DC-DC converter switching at 2 Mhz.

Integrated motor drives

At TTPi, we are building the next generation of integrated motor drives – compact, efficient, and high-performing. Our technology uses minimal passive components and innovative topologies to reduce losses and the size of thermal management systems, so entire drives fit into the motor housing.

Our drives come with advanced features, like a controllable grid displacement factor that helps boost power quality and efficiency. Everything is controlled through a single FPGA, enabling fast, precise real-time operation. We also bring expertise in innovative converter technologies such as hybrid multi-level or auxiliary resonant commutated pole (ARCP) inverter designs—key enablers for fully integrated variable speed motors for automotive and industrial applications. This work is demonstrated in the VIDAR smart motor (video and picture right), launched in March 2025.

We’re pushing the boundaries further with new innovations, like our upcoming motor control patent developed as part of the Bentley OCTOPUS project in which we have developed different control algorithms for individual motor types. This includes, high precision encoderless control for synchronous motors, which operate at very low speed, to AI based control of highly non-linear motors.

Embedded power modules

At TTPi, we are always thinking ahead – and embedded die technology is part of our roadmap. It offers a promising path towards compact, cost-effective “converter-in-package” systems. Using 2.5D and 3D manufacturing techniques, the area above the die becomes a usable, structural and functional zone that can be used for gate drivers, power planes and thermal management. This means smarter modules with high-frequency switching, optimised passive components and layouts, and built-in, air or liquid-cooled thermal management. We also plan to integrate EMI filtering and suppression. While no fully embedded high-power ‘converter-in-package’ solution exists in the market today, TTPi is at the forefront of work to turn this concept into a manufacturable, scalable reality.

CONTACT US ABOUT PRODUCTS, PROTOTYPES & PARTNERSHIPS